-

Highlight

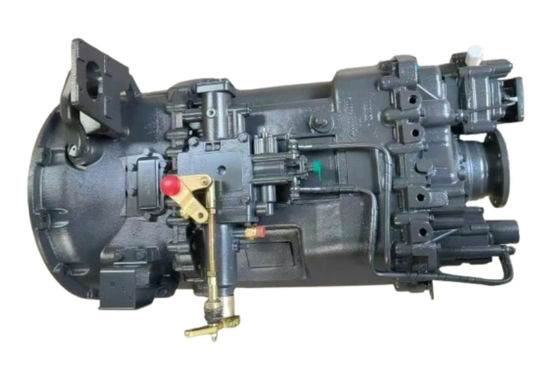

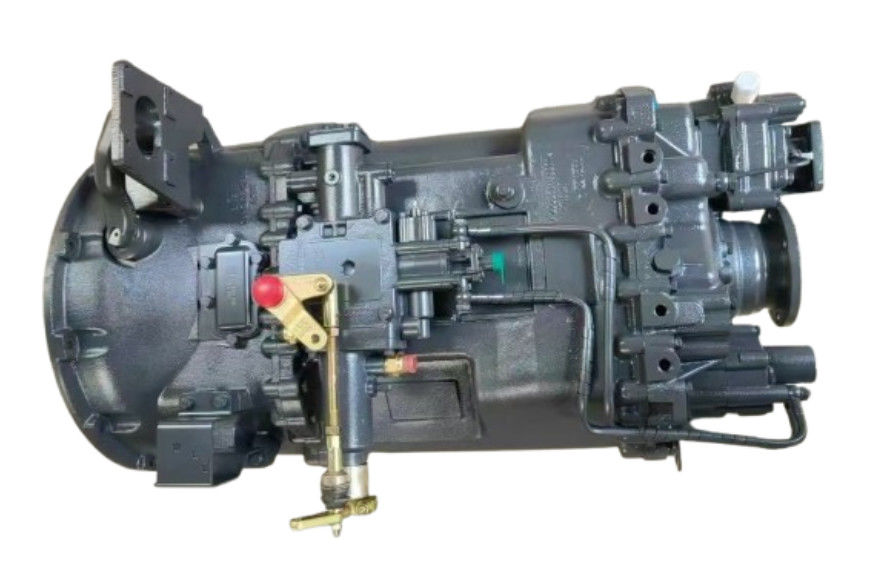

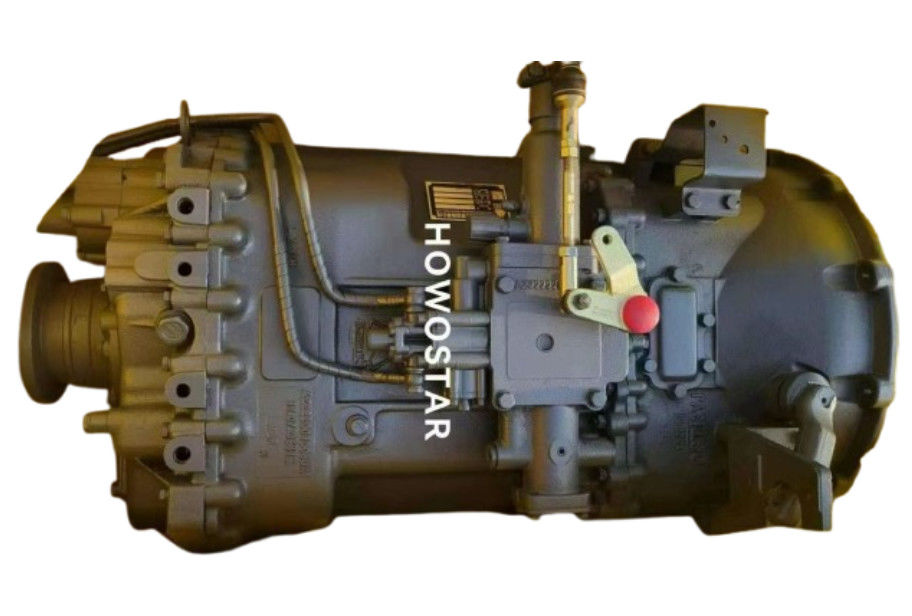

HOWO transmission assembly HW19712

,truck transmission replacement part

,HOWO truck transmission with warranty

-

Place of OriginCHINA

-

Brand NameHOWOSTAR

-

Model NumberHOWO Tansmission Assy HW19712

-

Minimum Order Quantity1

-

Packaging Detailswooden crate

HOWO Tansmission Assy HW19712

Functions and Applications of HW19712 Transmission Assembly

The HW19712 transmission assembly, a 12-speed manual gearbox developed byChina National Heavy Duty Truck Group (CNHTC), is engineered for heavy-duty commercial vehicles, offering optimized power delivery, durability, and adaptability across diverse operational scenarios. Its key functions and applications are as follows:

1. Multi-Gear Configuration for Adaptive Power Transmission

• 12 Forward + 2 Reverse Gears: The HW19712 provides12 forward gears and 2 reverse gears, enabling precise torque and speed adjustments for heavy loads, steep inclines, and highway cruising.

• Example: Lower gears (1–6) deliver high torque for off-road or construction use, while higher gears (7–12) enhance fuel efficiency during highway transport.

• Max Input Torque: Handles up to1900 N·m (2100 N·m for HW19712C/CL variants), ensuring reliability under extreme loads.

2. Robust Structural Design for Heavy-Duty Use

• Two-Section Layout: Comprises amain box (6 forward gears)and anauxiliary box (2 gears), combining to form 12 forward speeds.

• Dual Countershaft Mechanism: The main box uses two countershafts spaced 180° apart, reducing torque load per shaft and minimizing axial length.

• Planetary Gear Reduction: The auxiliary box employs a planetary gear system for high torque transmission, compact design, and extended service life.

3. Advanced Gear Shifting Mechanisms

• Sliding Sleeve Synchronization: Shifts are executed via sliding sleeves with 35° taper angles, allowing automatic centering and synchronization during engagement.

• Manual Main Box + Pneumatic Auxiliary Box: The main box is manually shifted, while the auxiliary box uses pneumatic control for seamless high/low-range switching.

4. Load Distribution and Stress Reduction

• Floating Main Shaft: The main shaft operates in a floating state, distributing radial forces evenly and eliminating traditional needle bearings, thus reducing wear and improving reliability.

• Optimized Gear Meshing: "Tooth Alignment" ensures proper gear engagement, minimizing noise and vibration.

5. Efficient Lubrication System

• Forced + Splash Lubrication: Combines a high-flow pump for forced lubrication of critical components (e.g., synchronizers, bearings) with splash lubrication for gears.

• Integrated Oil Filter: Maintains oil cleanliness, extending transmission life.

6. Power Take-Off (PTO) Compatibility

• Rear PTO Integration: Supports optional PTOs (e.g., HW50, HW70) for auxiliary equipment (e.g., hydraulic pumps, cranes), with forced lubrication eliminating the need for additional oil.

7. Lightweight and Compact Design

• Aluminum Alloy Option: Optional aluminum housing reduces weight by up to 15% compared to steel, improving fuel economy and payload capacity.

Key Specifications for HW19712 Transmission Assembly

Parameter Details

Model HW19712 (Standard), HW19712C/CL (High-Torque)

Gear Configuration 12F + 2R

Max Input Torque 1900 N·m (Standard), 2100 N·m (C/CL)

Rated Speed 2600 rpm

Weight 357 kg (Standard), 392 kg (C/CL)

Oil Capacity 13–14.5 L

Total Length 915 mm

Head Gear Ratio 11.8 (Standard), 15.01 (Alternative)

Industrial Applications

• Logistics & Transport: Long-haul trucks benefit from the 12-speed range and fuel efficiency.

• Construction & Mining: Dump trucks and excavators leverage high torque and durability for rough terrain.

• Specialized Vehicles: Fire trucks, cement mixers, and military vehicles utilize PTO compatibility for auxiliary systems.

The HW19712 transmission assembly stands out for itsmulti-gear adaptability, robust construction, and efficient lubrication, making it a cornerstone of heavy-duty commercial vehicle engineering. Its compatibility with PTOs and optional aluminum housing further enhances its versatility across industries.